No wonder Digital Twin is changing the world. Let’s understand what lies beneath.

Last Updated on February 2, 2022 by Editorial Team

Author(s): Supriya Ghosh

Originally published on Towards AI the World’s Leading AI and Technology News and Media Company. If you are building an AI-related product or service, we invite you to consider becoming an AI sponsor. At Towards AI, we help scale AI and technology startups. Let us help you unleash your technology to the masses.

IoT

No wonder Digital Twin is changing the world. Let’s understand what lies beneath?

What is a Digital Twin?

A Digital Twin is a virtual replica of an object, a product or a system, a service, process, or even a person which is connected or paired with its physical counterpart and uses real-time data and their updates for simulation, applying machine learning algorithms and reasoning to predict problems before they can occur and aids in decision-making. This digital replica can be of a single object or the complete system or even a system of systems.

In other words, Digital Twins are computer programs that use real-world data to create simulations that can predict how a product or process will perform. These programs integrate well with the internet of things (Industry 4.0), artificial intelligence, machine learning, and analytics to enhance the output.

Digital Twin — 2 terms coined together

1. Actual physical asset in operation

2. And its Up-to-date/latest virtual or digital representation

In terms of the virtual representation of the asset in operation, the Digital Twins includes relevant historical data about the asset, captures the current data, and evaluates the condition of the asset based on that to predict future behavior, more importantly, refine the control, or optimize operation.

An important point to note here is that –

A digital twin can model:

· A component

· A system of components

· A system of systems

These models reflect the operating asset’s current environment, age, and configuration, which generally involves the direct feeding of asset data into tuning algorithms.

Some areas where Digital Twins prove useful

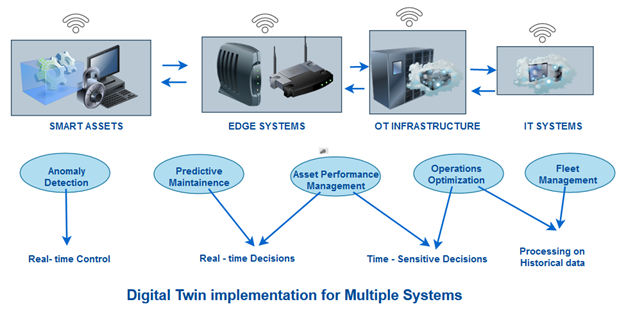

Digital Twins are used in a variety of applications and a few of them are anomaly detection, asset management, fleet management, etc. Implementing multiple digital twins for different applications is possible which can be deployed into the system topology together. The digital twins can be executed on the smart asset, at the edge, or on the IT/OT layers depending on the response time required by the application.

Examples stated can be of optimizing maintenance schedules based on remaining useful life estimation (RUL) of an asset or optimizing current asset operations, using simulation to create future “what-if” scenarios, and many more.

Once the digital twin is available and up-to-date, it can be used in any number of ways to predict future behavior, refine the control, or optimize the operation of the asset. Some examples include simulating the sensors that are not present on the actual asset, simulating future scenarios to refine current and future operations, or using the digital twin to extract the current operational state by sending in real-time inputs.

Digital Twin Usage within aforesaid application areas

1. Operations Optimization

Relevant parameters and variables which are replicas of real-time data are used to trigger innumerable what-if simulations to evaluate readiness and necessary adjustments to the current system. This approach optimizes system operations and mitigate risk, reduces cost, and gain system efficiencies.

2. Anomaly Detection

The digital twin model runs in parallel to the real assets and immediately flags anomalies in the operational behavior that deviates from expected (simulated) behavior to avoid catastrophic damage.

1. Predictive Maintenance

Digital twin models are used in industrial automation and machinery applications to determine the remaining useful life and the most appropriate time to service or replace equipment.

2. Fault isolation

Anomalies generally trigger an array of simulations to isolate the fault and identify the root cause so that the system can take appropriate action and either restore back to the corrective state or else can get repaired by the engineers.

Benefits of Using Digital Twins

- Asset history

Digital twin captures the real asset’s history. Since every time the digital twin model represents the actual asset’s current state i.e., it keeps updating periodically hence over time, the past states captured at different intervals of time become the asset’s history. These historical data and states are used to understand how the asset behaved under faults and under different conditions and the effect on the system efficiency.

2. Maintenance Strategies

The ability to monitor the whole system using digital twins brings additional advantages in terms of planning operational events and improving maintenance strategies. Let’s imagine a situation where one of the assets within the complete system is expected to fail soon. Using digital twins, one can assess how this will affect the efficiency of the entire system and what it can cost?

Based on this analysis, one can either:

1. Order replacements and run the asset in a sub-optimal state until one gets the new parts.

- Pay a high amount for shipping and get the parts immediately to schedule maintenance as soon as possible.

3. Simulate Future Scenarios

Understanding the history of the assets, digital twins also help with future planning as they can simulate hundreds of future scenarios to see how different factors or different operating conditions affect the performance. The approach basically helps manage assets and optimize operations by informing maintenance staff about the expected failures in advance so future repairs and replacements can be planned accordingly.

How does the digital twin model work?

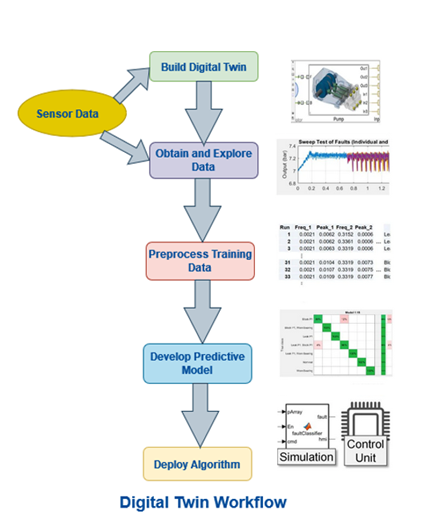

An up-to-date representation of the asset is created by building a model that gets updated with the incoming data from the asset — such as data transmitted from sensors and current operating conditions. The digital twin model then represents the current state of the asset.

These sensor measurements and operating conditions are sent from the actual asset to the model. The model takes these readings and outputs the current state of the asset.

The decision on what to model, and subsequently how to model it, rests on the system knowledge and application need.

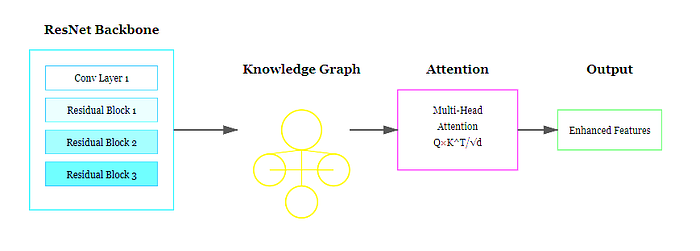

Modeling Methods

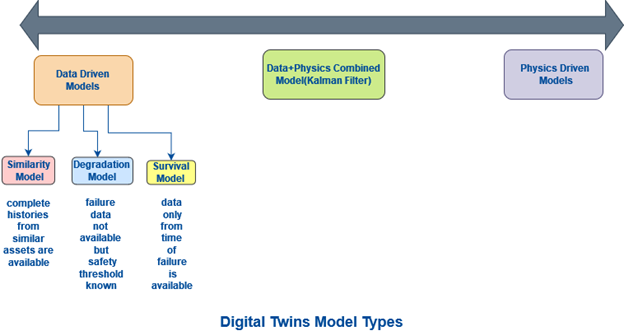

Modeling methods are grouped into two types: physics-based methods (e.g., mechanical modeling) and data-driven methods (e.g., deep learning).

Let’s say optimizing maintenance schedules by estimating the remaining useful life (RUL) of the asset is our use case.

Knowledge of the type of data from the asset will determine which model will be used.

Data-Driven Models

If complete histories from similar machines are available, then similarity models are used.

If data only from the time of failure is available, then survival models are used.

If failure data is not available but the safety threshold is known, degradation models can be used to estimate RUL.

Now suppose our use case is to simulate future scenarios and monitor how the complete system will behave under those scenarios. Then a physics-based model can be used. A physical model can be created by connecting mechanical and hydraulic components if present and the model is fed with data from the asset, and its parameters are estimated and refined with this incoming data to keep the model up to date. This can help in injecting different types of faults and simulate the asset’s behavior under different fault conditions.

Modeling Methods: Data and Physics Combined — Kalman Filters

Similarly, the third type of model is the Kalman filter which can also be used as a digital twin and can model the degradation of the asset as one of the states and periodically refresh this state to represent the current condition of the asset.

Digital Twin Workflow in Applications

This offers several advantages

1. Equipment Downtime Reduction by preventing failures as it can be predicted in advance.

2. Inventory Management by identifying faults and getting insights into which parts need repair or replacement.

3. Entire system Management, What-If Simulations, and Operational Planning by monitoring the system simulating future scenarios, and making comparisons with the aim of increasing the overall efficiency of the system and enhancing operational planning.

Conclusion –

Digital twins are emerging as a hot technology, particularly in manufacturing and the Industrial Internet of Things. Depending on the use cases, digital twin avatars can be customized as per needs. Every digital twin is a unique representation to a certain extent. The ability to create a digitized copy of an actual physical asset and measure how that model responds and reacts to different inputs is the fundamental breakthrough that is driving the adoption and adaption of digital twin technologies.

Thanks for reading!!!

References –

2. https://www.ibm.com/topics/what-is-a-digital-twin

You can follow me on medium as well as

LinkedIn: Supriya Ghosh

And Twitter: @isupriyaghosh

No wonder Digital Twin is changing the world. Let’s understand what lies beneath. was originally published in Towards AI on Medium, where people are continuing the conversation by highlighting and responding to this story.

Join thousands of data leaders on the AI newsletter. It’s free, we don’t spam, and we never share your email address. Keep up to date with the latest work in AI. From research to projects and ideas. If you are building an AI startup, an AI-related product, or a service, we invite you to consider becoming a sponsor.

Published via Towards AI

Take our 90+ lesson From Beginner to Advanced LLM Developer Certification: From choosing a project to deploying a working product this is the most comprehensive and practical LLM course out there!

Towards AI has published Building LLMs for Production—our 470+ page guide to mastering LLMs with practical projects and expert insights!

Discover Your Dream AI Career at Towards AI Jobs

Towards AI has built a jobs board tailored specifically to Machine Learning and Data Science Jobs and Skills. Our software searches for live AI jobs each hour, labels and categorises them and makes them easily searchable. Explore over 40,000 live jobs today with Towards AI Jobs!

Note: Content contains the views of the contributing authors and not Towards AI.