How to Monitor a Computer Vision Model in Production?

Last Updated on January 29, 2024 by Editorial Team

Author(s): Maciej Balawejder

Originally published on Towards AI.

One of the unfortunate properties of computer vision models is that performance deteriorates with time, leading to less reliable results. Since these models are trained on static images when deployed in production environments with constantly changing data, the patterns they’ve learned become outdated.

Think about the road sign detection model in cars. If the country decides to replace older road signs with newly designed ones, the model will have difficulty identifying them. As a result, the driver could get inaccurate speed limit information on the car dashboard, potentially leading to an accident or, at best, a speeding ticket. To prevent such a failure, the model needs a monitoring system that can detect and explain why it is inaccurate.

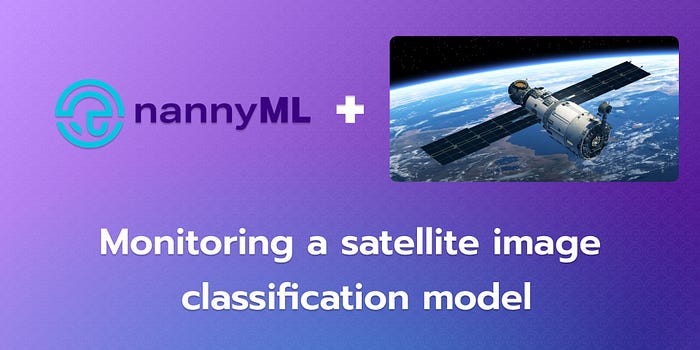

In this blog, we will create a system to monitor both the performance and data shifts of our satellite image classification model.

Let’s get into it!

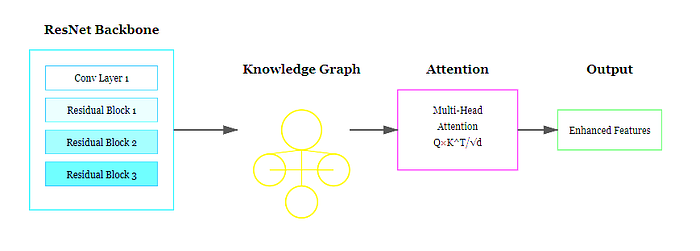

Monitoring system workflow.

The key initial step of a monitoring system in production is tracking performance metrics like accuracy. When performance drops, it means there’s an issue in the data that must be analyzed and resolved.

In some computer vision applications, such as quality inspection of car manufacturing parts, evaluating performance is relatively straightforward. If the model predicts good quality, the part… Read the full blog for free on Medium.

Join thousands of data leaders on the AI newsletter. Join over 80,000 subscribers and keep up to date with the latest developments in AI. From research to projects and ideas. If you are building an AI startup, an AI-related product, or a service, we invite you to consider becoming a sponsor.

Published via Towards AI

Take our 90+ lesson From Beginner to Advanced LLM Developer Certification: From choosing a project to deploying a working product this is the most comprehensive and practical LLM course out there!

Towards AI has published Building LLMs for Production—our 470+ page guide to mastering LLMs with practical projects and expert insights!

Discover Your Dream AI Career at Towards AI Jobs

Towards AI has built a jobs board tailored specifically to Machine Learning and Data Science Jobs and Skills. Our software searches for live AI jobs each hour, labels and categorises them and makes them easily searchable. Explore over 40,000 live jobs today with Towards AI Jobs!

Note: Content contains the views of the contributing authors and not Towards AI.