Local Binary Pattern for The Evaluation of Surface Quality of Dissimilar Friction Stir Welded…

Last Updated on July 28, 2020 by Editorial Team

Author(s): Akshansh Mishra

Engineering, Machine Learning

Local Binary Pattern for The Evaluation of Surface Quality of Dissimilar Friction Stir Welded Joints

Friction Stir Welding process is an advanced solid-state joining process which finds application in various industries like automobiles, manufacturing, aerospace, and railway firms. Input parameters like tool rotational speed, welding speed, axial force, and tilt angle govern the quality of the Friction Stir Welded joint. Improper selection of these parameters further leads to the fabrication of the joint of bad quality resulting in groove edges, flash formation, and various other surface defects. In the present work, a texture-based analytic machine learning algorithm known as Local Binary Pattern (LBP) is used for the extraction of texture features of the Friction Stir Welded joints which are welded at a different rotational speed. It was observed that the LBP algorithm can accurately detect any irregularities present on the surface of the Friction Stir Welded joint.

Introduction

Friction Stir Welding is a solid-state joining process which was developed by The Welding Institute (TWI) mainly for joining the light-weight materials like aluminum and magnesium alloys (Mishra and Ma, 2005; Pratik and Vishvesh, 2019; Ramona and Santos Jorge, 2013). The Friction Stir weldability of aluminum alloys is compared to other conventional fusion welding process shown in Fig. 1. Friction Stir Welding process results in high-quality welds but the welding performance mainly depends on the proper selection of various input parameters like pin temperature, tool rotational speed, feed rate, welding speed, temperature distribution, rotating tool torque, applied downward forging force on tool shoulder, etc.

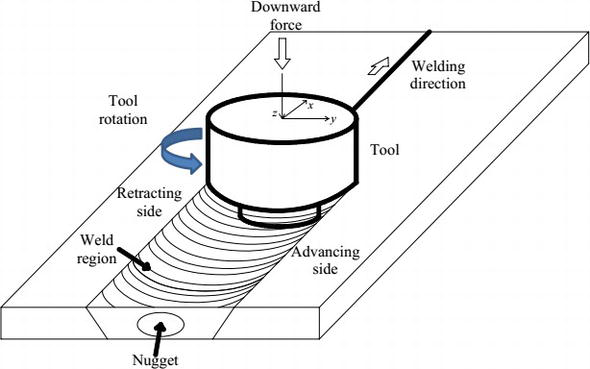

The working mechanism of the Friction Stir Welding process is shown in Fig. 2.

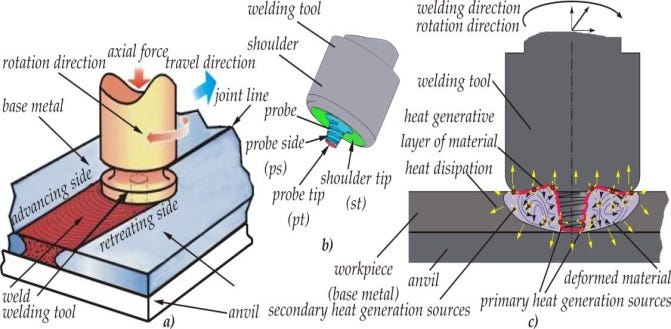

The main beauty of the Friction Stir Welding process is that it uses a non-consumable metallic tool which is harder than the base material to be joined (Rai et al., 2011). The tool consists of a shoulder and pin as shown in Fig. 3b). The tool is plunged inside the base material by applying a downward force. The Friction Stir Welding tool possesses two types of speed i.e., Rotational speed and Traverse speed in the welding direction. Due to the rotation of the rotating tool, there is a generation of friction between the workpiece and the rotating tool which results in plastic deformation of the workpiece as shown in Fig. 3c).

Due to the generated localized heat, the workpiece get soften around the probe or pin region which results in the movement of softening or plasticized material from the front part of the probe to the back part of the probe. The welded joint is formed by deforming the material at temperatures below the melting point of parent material (Mijajlović and Milčić, 2012). At a very cold welding condition defects such as void formation and non-bonding can occur while at very hot welding condition issues such as degradation of the strength of the joint can occur as well as there is a formation of collapsible nugget within the stir zone occurs (Rudrapati, 2019).

In the present work, a machine learning algorithm called Local Binary Pattern (LBP) has been developed for evaluating the surface defects like lack of penetration and flash formation of dissimilar Friction Stir Welded Ultrafine Grained 1050 and 6061-T6 Aluminum Alloys.

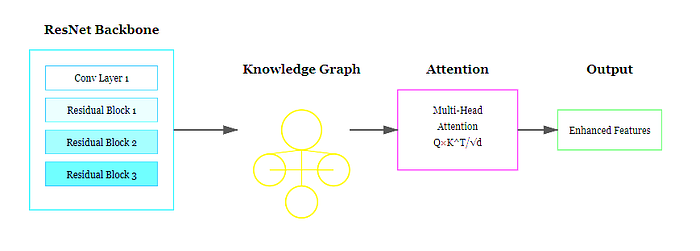

Working of Local Binary Pattern

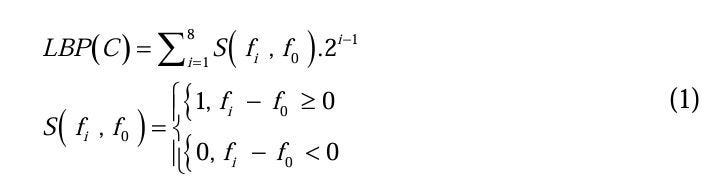

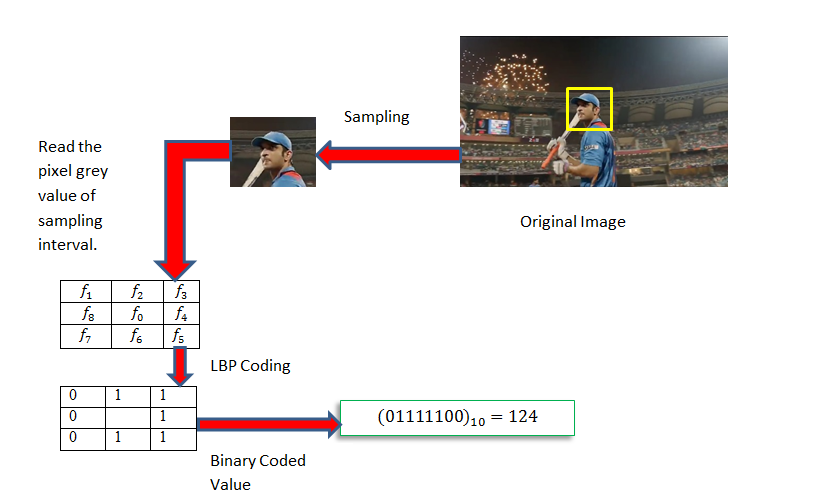

Local Binary Pattern is an important image texture analysis machine vision algorithm that is tolerant against any type of illumination changes in a real-time application (Cai et al., 2020). Local Binary Pattern creates a grey value difference between the neighborhood pixels and the center pixel in the sampling area. In a rectangular neighborhood with a size of 3´3, the Local Binary Pattern is defined. Firstly, the conversion of the color image into a greyscale image is done with a greyscale value of 0~255. As a sampling point, pixels of the rectangular area is used. f0 is the grey value of the center pixel and f1, f2, f3…, f8 are the greyscale values of the 8 pixels around it. The corresponding position is encoded as 1 when fi is greater than equal to f0. The corresponding position is encoded as 0 when fi < f0 as shown in Fig. 4.

Equation 1 describes the coding formula for Local Binary Pattern algorithm:

Kamani et al. (2011) used the Local Binary Pattern for classification of the car body and automatic paint defect detection. It was observed that the identification and classification of defects can be done with high accuracy. Mahram et al. (2012) detected cracks and wood knots in order to classify stable and strong woods by using Local Binary Pattern algorithm. Aghdam et al. (2012) worked on defect detection using decision trees applied to LBP based features. The results showed that in comparison to other traditional schemes, the proposed classification system is faster. Luo et al. (2018) for time-efficient steel surface defect classification used generalized completed Local Binary Pattern. The results showed that the method can be implemented in an online monitoring system for a hot-rolled steel strip.

Experimental Procedure

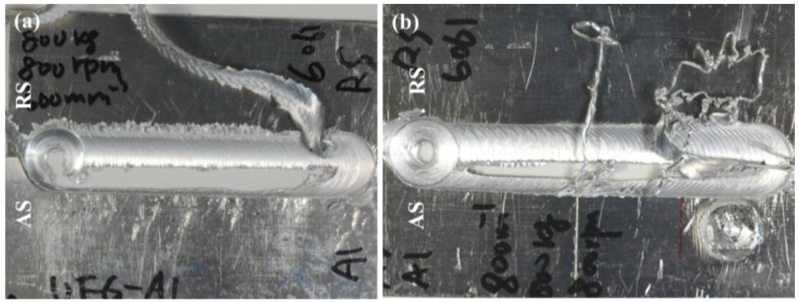

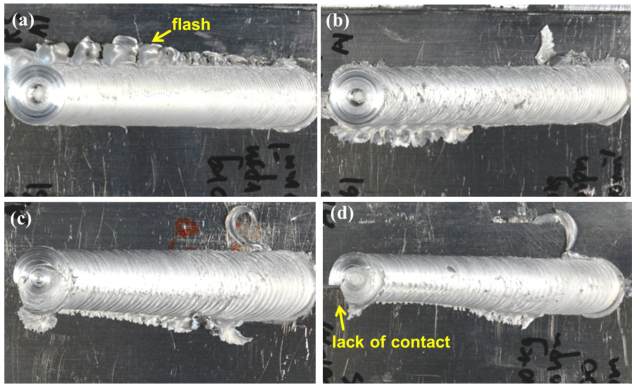

Friction Stir Welding was carried out on a 2 mm thick plate of commercial AA 6061-T6 and Ultrafine grained 1050 aluminum alloy plates (Sun et al., 2016). The material used for the Friction Stir Welding tool was tool steel whose shoulder geometry was concave shaped. During the welding operation, a constant load of 8000 KN was applied at a constant rotational speed of 800 rpm and varying traverse speed of 400, 600, 800, 1000 mm/min. Figure 5a shows the dissimilar Friction Stir Welded joint obtained at tool rotational speed of 800 rpm and 600 mm/min while Fig. 5b shows the dissimilar Friction Stir Welded joint obtained at tool rotational speed of 800 rpm and tool traverse speed of 800 mm/min. Similarly, Fig. 6a shows the dissimilar Friction Stir Welded joint obtained at the tool rotational speed of 800 rpm and tool traverse speed of 400 mm/min, Fig. 6b shows the joint obtained at the tool rotational speed of 800 rpm and tool traverse speed of 600 mm/min, Fig. 6c shows the joint obtained at the tool rotational speed of 800 rpm and tool traverse speed of 800 mm/min, Fig. 6d shows the joint obtained at the tool rotational speed of 800 rpm and tool traverse speed of 1000 mm/min.

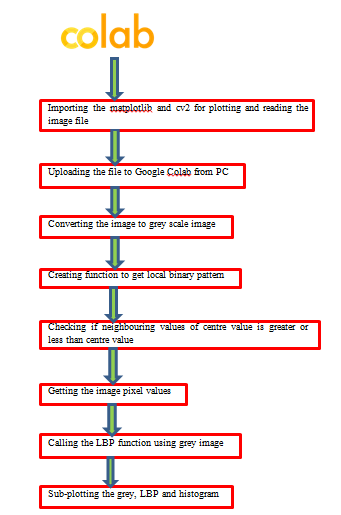

The obtained images were cropped and were subjected to various operations as shown in Fig.7.

The Python programming was used for coding the algorithm and to carry out the modeling.

Results and Discussions

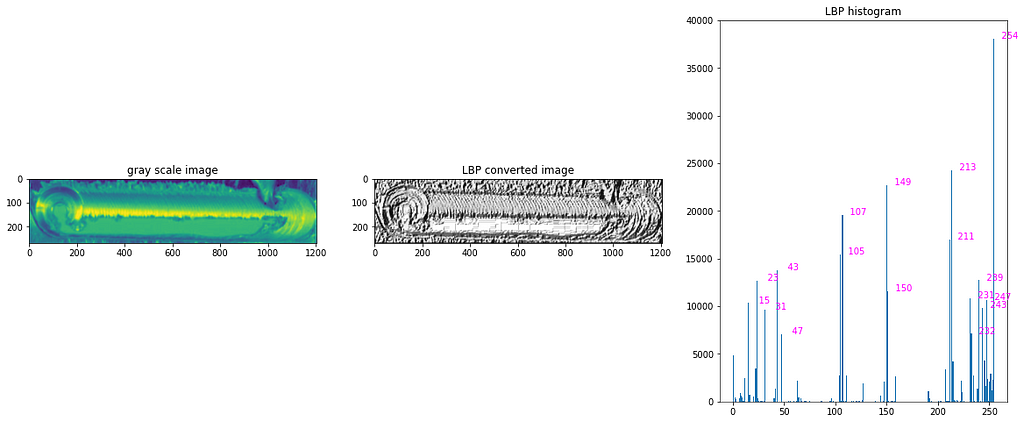

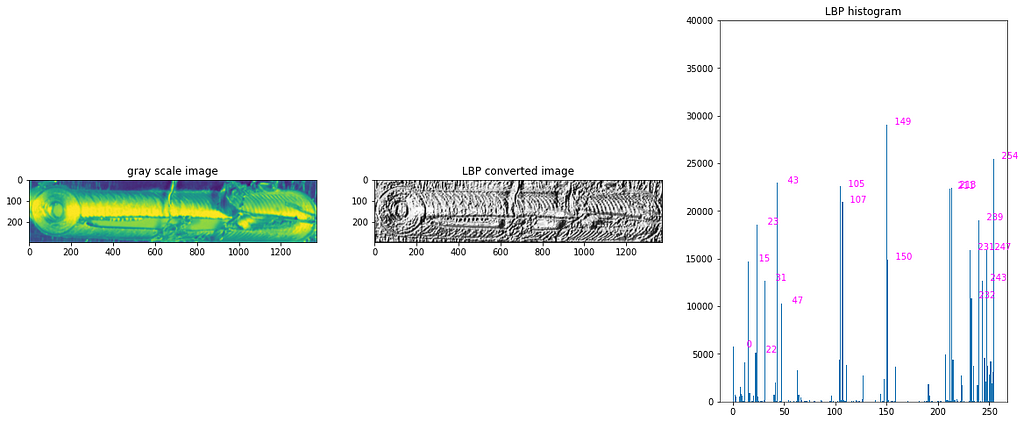

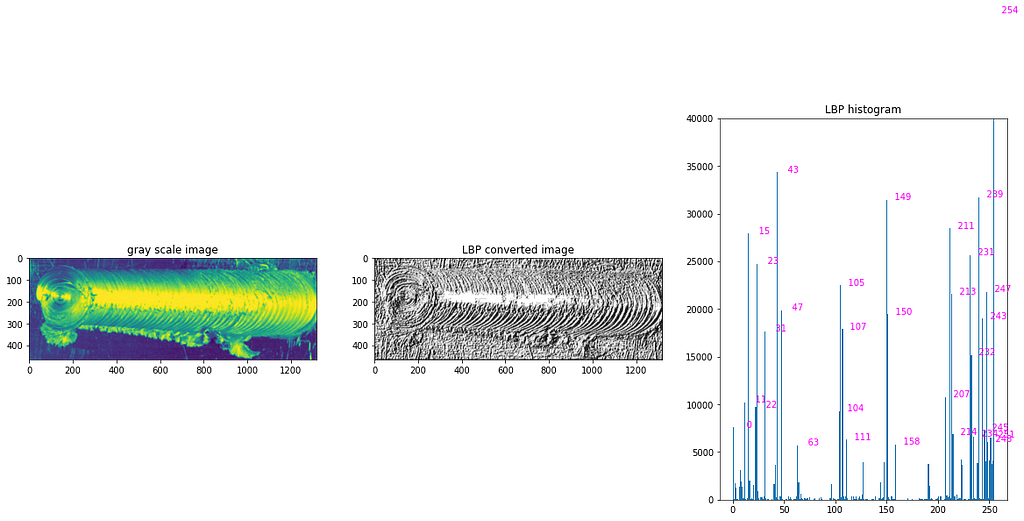

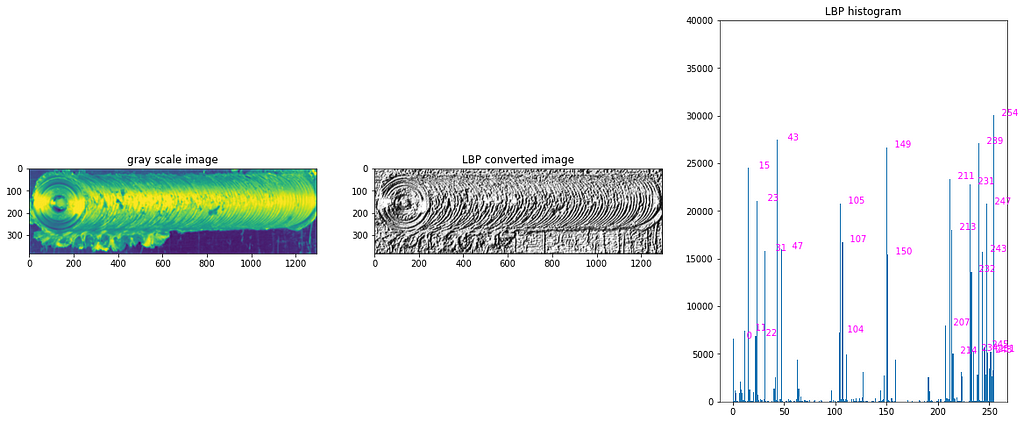

The grey images, Local Binary Patterns, and histograms of the Friction Stir Welded were obtained as shown in Fig. 8–11. Local Binary Pattern can easily display the non-homogeneous nature of the image. So, various surface defects like flash formation, groovy edges, and lack of contact present in Friction Stir Welded joints can be easily detected by implementing Local Binary Patterns.

Conclusion

In this study, the Local Binary Pattern algorithm is proposed for evaluating the surface quality of Friction Stir Welded joints. Local Binary Pattern algorithm easily validated the detection of surface defects like lack of contact and flash formation in Friction Stir Welded joints. It is observed that when 6061-T6 is on the retreating side then the LBP converted image shows a more non-homogeneous nature in comparison to the arrangement when 6061-T6 is on advancing side also the former arrangement shows fewer peak values in histograms. So, it can be concluded that the Local Binary Pattern (LBP) algorithm can be successfully implemented in visual inspection and in real-time monitoring.

References

Aghdam, S. R., Amid, E., & Imani, M. F. (2012, July). A fast method of steel surface defect detection using decision trees applied to LBP based features. In 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA) (pp. 1447–1452). IEEE.

Cai, Y., Xu, G., Li, A., & Wang, X. (2020). A Novel Improved Local Binary Pattern and Its Application to the Fault Diagnosis of Diesel Engine. Shock and Vibration, 2020.

Kamani, P., Noursadeghi, E., Afshar, A., & Towhidkhah, F. (2011, November). Automatic paint defect detection and classification of car body. In 2011 7th Iranian Conference on Machine Vision and Image Processing (pp. 1–6). IEEE.

Luo, Q., Sun, Y., Li, P., Simpson, O., Tian, L., & He, Y. (2018). Generalized completed local binary patterns for time-efficient steel surface defect classification. IEEE Transactions on Instrumentation and Measurement, 68(3), 667–679.

Mahram, A., Shayesteh, M. G., & Jafarpour, S. (2012, July). Classification of wood surface defects with hybrid usage of statistical and textural features. In 2012 35th International Conference on Telecommunications and Signal Processing (TSP) (pp. 749–752). IEEE.

Mijajlović, M. (2012). Investigation and development of analytical model for estimation of amount of heat generated during FSW (Doctoral dissertation, Ph. D. thesis, Faculty of Mechanical Engineering Nis, University of Nis, Nis, Serbia).

Mijajlović, M., & Milčić, D. (2012). Analytical model for estimating the amount of heat generated during friction stir welding: application on plates made of aluminium alloy 2024 T351. Welding processes, 247–274.

Mishra, R. S., & Ma, Z. Y. (2005). Friction stir welding and processing. Materials science and engineering: R: reports, 50(1–2), 1–78.

Pratik, H.S., & Vishvesh, J. B. (2019). Friction stir welding of aluminium alloys: An overview of experimental findings–Process, variables,development and applications. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, 233(6), 1191–1226.

Rai, R., De, A., Bhadeshia, H. K. D. H., & DebRoy, T. (2011). friction stir welding tools. Science and Technology of welding and Joining, 16(4), 325–342.

Ramona, G., & Santos Jorge, F. D. (2013). Friction stir welding development of aluminium alloys for structural connections. Proceedings of the romanian academy, Series A, 14(1), 64–71.

Rudrapati, R. (2019). Recent Advances in Joining of Aluminum Alloys by Using Friction Stir Welding. In Mass Production Processes. IntechOpen.

Sun, Y., Tsuji, N., & Fujii, H. (2016). Microstructure and mechanical properties of dissimilar friction stir welding between ultrafine grained 1050 and 6061-t6 aluminum alloys. Metals, 6(10), 249.

Local Binary Pattern for The Evaluation of Surface Quality of Dissimilar Friction Stir Welded… was originally published in Towards AI — Multidisciplinary Science Journal on Medium, where people are continuing the conversation by highlighting and responding to this story.

Published via Towards AI

Take our 90+ lesson From Beginner to Advanced LLM Developer Certification: From choosing a project to deploying a working product this is the most comprehensive and practical LLM course out there!

Towards AI has published Building LLMs for Production—our 470+ page guide to mastering LLMs with practical projects and expert insights!

Discover Your Dream AI Career at Towards AI Jobs

Towards AI has built a jobs board tailored specifically to Machine Learning and Data Science Jobs and Skills. Our software searches for live AI jobs each hour, labels and categorises them and makes them easily searchable. Explore over 40,000 live jobs today with Towards AI Jobs!

Note: Content contains the views of the contributing authors and not Towards AI.