Technological Game Changer — Internet of Avionics things(IOAT) has engulfed Aviation like fire

Last Updated on July 25, 2021 by Editorial Team

Author(s): Supriya Ghosh

IoT

Technological Game Changer — Internet of Avionics things(IOAT) has engulfed Aviation like fire

Leveraging IOT’s endless and exhilarant possibilities.

The capabilities go much deeper and the sky is not the limit.

So let’s ride this wave of transformation

Introduction

The Internet of Things (IoT) is a buzzword that has now encompassed all facets of our lives. It is an umbrella technology which is progressively covering any physical domain. It has been extending from Automotive, Robotics, Consumer electronics, Healthcare, Industrial Automation, Logistics, Energy, Retail, Sport and fitness, Wearable’s, Telecom, Home Automation, Insurance, Banking, Construction, Hotels, Agriculture, National security and whatnot. The list by no means is exhaustive. The potential of IoT is huge. The aerospace industry is also not left behind in this revolution.

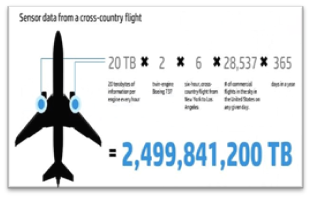

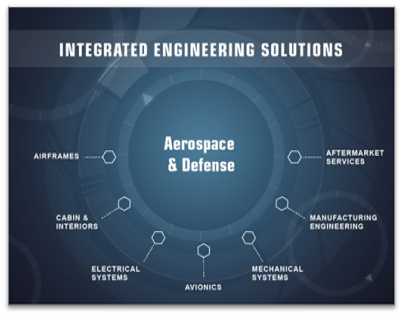

The Internet of Things (IoT) in the aerospace industry has grown enormously. It started with engines and has embraced avionics systems to a great extent now. The key factor in this development is the myriad of sensors that are embedded into every system in an aircraft and generate huge amounts of data that are processed in real-time. A term coined, Internet of Aircraft Things (IOAT) has penetrated into various segments in the aerospace industry. Aircraft connectivity has greatly increased now with rising in connected devices and better aircraft data networks and increased bandwidth. And the explosion is so huge that it has the capability to drive the black box to simply a backup device. Various segments of the industry now want to remain connected 24/7 and thus the new generation of aircraft driven by connectivity, data analytics, and Internet of Things (IoT) is reaching levels which are exemplary.

IoT Applications across the Aerospace Industry

IoT in Aircraft Engines

The information generated in-flight by the engine sensors is not only used to optimize jet fuel consumption & fuel burn which leads to improvement in engine efficiency but also to improve performance in engine noise and emissions, an adjustment in thrust levels, directly recording engine cycles and flight hours, adjust the way aircraft flies, manage and repair aircraft engines at the early stage and detect minor faults before they become major ones. They also generate continuous operational performance data during all phases of flight which optimizes the performance of the engine by detecting trends and anomalies so as to reduce unplanned engine removals. This improves the overall health of the aircraft and in the long term reduces maintenance costs. With this already GTF (Geared Turbo Fan) engines are demonstrating a reduction in fuel consumption by 10% to 15%.

Predictive analytics for engines is a significant driver of innovation in the future. Improved fuel performance is all set to save airlines $75,000 to $100,000 per year per aircraft. Taxing on one engine on departure has already translated into saving 60kg of fuel per flight for one of the airlines and many are on the same path to follow. It can be rightly said that these Internet of Aircraft Things solutions will lead to additional business and increased revenue for engine manufacturers and OEMs.

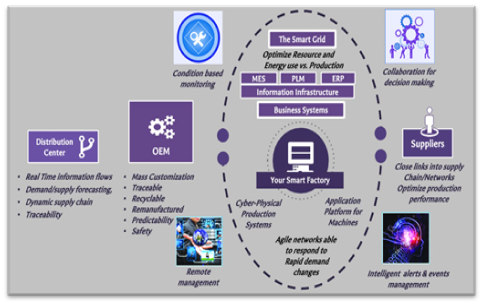

IoT in ‘Factory of the Future’

The aerospace sector is expected to gain more than 40% improvement in factory efficiencies by the application of IoT and Data Analytics (Industrial Automation) and they call it ‘Factory of the Future’. IoT is applied not only to the products but to the tools its workers use during manufacturing processes to tighten thousands and thousands of bolts. By connecting both the people and those tools to an IoT platform, manufacturing optimizes. One of the use cases is: A worker on the factory floor uses a tablet or smart glasses to scan an airplane’s metal body and determine what size of the bolt is needed in a given hole, and the torque required to install it. This information is instantly sent to a robotic tool, which completes the task.

This approach helps in aligning thousands of steps in the assembly of airplanes so as to optimize the value chain. This is what is called the “cyber-physical systems approach” An aircraft on average uses as many as 400,000 bolts and screws alone and more than 1,100 different tools. With these tools connected, the process is not only efficient and effective but more reliable and robust than if the bolts were tightened manually. It is proven that the IoT will redefine manufacturing processes. It will change global competitiveness with increased collocation of design, manufacturing, and services.

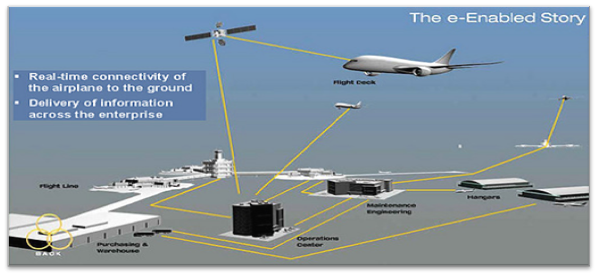

IoT in Avionics systems

Avionics systems transmit data and information to the maintenance teams on the ground in real-time. The Systems are able to provide notification to suppliers of parts that need to be replaced and provide alerts to maintenance personnel, minimize the aircraft downtime because of not having the right parts at the right location. Also, they are able to update dashboards to flight information, decide on optimized routes, instant decision making, support minor changes to flight plans and airspeed to reduce flight times, do forecasting based on flying hours & different tail numbers, and avoiding any such errors.

Intelligently they can detect an anomaly in associated hardware, software, or systems which can prevent accidents, do a predictive assessment of aircraft & component operations to generate customized maintenance programs, thus generating value for customers to not only reduce the time for Maintenance but also to recommend the optimal rescheduling of task sequences for Predictive Maintenance, view the health of the aircraft systems over some period of time and use their gradual deterioration to predict potential Risk-Scenarios and actually prevent it many times.

New aircraft models like Dreamliner’s for example come pre-designed with IP-enabled avionics systems that permit real-time data to be transmitted to the cockpit and to operations centers on the ground on flying conditions and discrepancies observed during the flight. Doing all of this preparation while the aircraft is still in the sky would help the airline to vastly reduce the chance of being placed in AOG (Aircraft on Ground), therefore helping it to reduce maintenance costs and also keep passengers happy. This way the airline will not have to fly any of its aircraft with the ‘Fly-Until-Broken’ philosophy. Preventing the aircraft from operating in ‘Not-Normal-But-Safe’ modes will save the airline much more in the long term (avoiding AOG situations). The Internet of Things promises to have widespread ramifications.

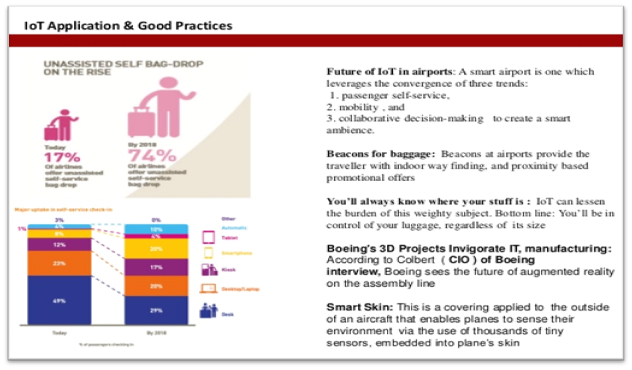

IoT in Aviation

Airports are also investing in IoT. London City Airport was an early adopter and it proceeded with plans to improve the passenger experience by using data transfer between machines to reduce lost luggage, flight delays, analyzing passenger traffic patterns at airports to estimate downtimes before aircraft departures, tracking pets in transit, and equipment monitoring and even cut down queues at the security line. People recognition software which is being used helps the airport to identify where passengers are and prevent queues before it causes inconvenience. In aviation, its effects could include reducing travel time and increasing safety and passenger comfort. For example, being able to track your bags from an app on either your Smartphone or tablet or a laptop and even the bags tracking your location.

How nice it will be if the bag senses you and enter the luggage area and selects the carousel you are standing closest to and enters that carousel. It’s not at all an imagination now. Permission-based sensing will be deployed on a large scale. Airlines will be in a position to make informed decisions about when to open and close the gates. Imagine the gate showing you on the display: ‘I see you have landed. It appears to be about a six-minute walk to your connecting flight gate. The gate will close in 10 minutes. All the equipment including, elevators, carousels for baggage, kiosks, bag-drop points, and boarding gates will be equipped with sensors. The staff and passengers will be connected. Equipment such as baggage trolleys and wheelchairs will also be connected too at the airport. Even buses used for transferring passengers, luggage, car parks area where frequent movements happen, etc will be embedded with sensors. Within the aircraft, sensors will be used for measuring cabin temperature, air conditioning, air quality, and light intensity levels and track catering and duty-free trolleys.

With around half of airlines using all these, for passengers, this will definitely translate into a better-informed journey and maximum comfort with less of anxiety.

IoT in Monitoring Air Turbulence

The Weather Companies are gathering vast amounts of real-time data from countless sensors on business aircraft while measuring and analyzing the same for monitoring air turbulence. This definitely counts towards improving passenger safety. TWC’s turbulence detection algorithm — known as the Turbulence Auto PIREP (Pilot Report) System (or TAPS) is being loaded on the aircraft-based communications servers of more than 6,800 business aircraft. Each server is able to access the plane’s sensors and other required avionics inputs. This allows the Turbulence Auto PIREP system to measure, calculate and analyze processed data for turbulence intensity. The processed data is then provided to the pilots in real-time as well as to ground control staff via Gogo’s air-to-ground and global satellite communications network.

All these will be highly advantageous as real-time collected data can be used to track turbulence and overall weather forecasts. This same data can be provided to aviation meteorologists for alerting weather-related risks at the global level. This will provide guidance to all flights that will be traveling through different regions (perhaps the more sensitive and impacted regions/areas) and improve airlines and passenger safety as per TWC.

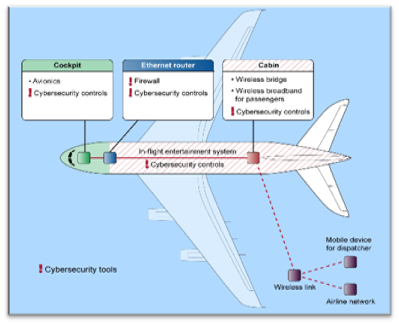

IoT in aircraft Connectivity and Entertainment

Satellite navigation systems are much more accurate than the current radar and radio navigation systems. This will support Airlines in getting the information about flights arrival /departure as well as their location much more precisely. Currently, many Airlines have started with the passengers being able to browse the Internet and conduct video conferencing when in-flight worldwide with ease. Passengers can log in through their laptops, Smartphone’s or tablets and then access a wide array of programs.

It has been suggested that for these devices planes can offer a free app before the trip and activate the program once the passengers aboard the planes. Those who have no tablet or Smartphone can loan a device from the airline. Furthermore, other options could be added like network games etc. Together, they could chat and play games in the network.

Additional services such as information on connecting flights, menu selection and drink orders to the crew or orders from the onboard shop would be easy to install. 75% of airlines plan to offer internet access along with multi-media file streaming directly to passenger devices by 2019.

IoT in Aircraft Passenger Convenience

Nowadays passengers are being provided with personalized instructions and updates as the live data from the airport’s systems are clubbed with Google maps. These not only include their booking details, flight time, location, etc but also the reminders for check-in, departure/arrival terminals, location of gates, directions towards bag drop point, and baggage-belt location for baggage claim in real-time. The passengers are directly notified to their mobile phones through messages and emails. The operations and customer service has been improved considerably by embedding beacons into luggage, baggage trolleys & trucks, bag tags, etc. for baggage management at some airports. To support customers with navigation and other personalized services based on their location at the airport, Bluetooth Low Energy (BLE) beacons have been deployed in test mode. One of the Airlines has recently started tracking and monitoring the condition of equipment, for eg. Life jackets and toolboxes with the help of beacons. This cuts down on the costs of inspecting them physically.

There are several displays, wearable devices such as watches, glasses and mobile phones, etc. available equipped with sensors to help passengers navigate and get alerts for all these services when on the ground. The same can happen in the air by the smart cabins with sensors fitted into seats that can monitor passenger’s tiredness and hydration levels to automatically adjust the cabin atmosphere or alert cabin crew to provide required hospitality. Recently on some domestic flights, GPS tracking services are launched. This monitors humidity and temperature conditions experienced by pets in transit as well as their location.

IoT: New Vision of Aerospace Operations and Business Models

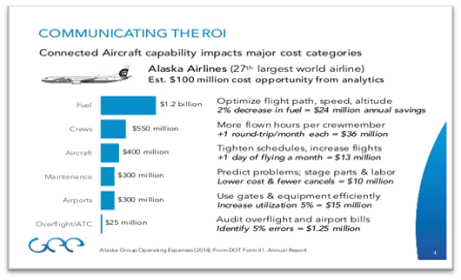

If a plane is not in the air, it loses money. One example is “Airbus China” which estimated the daily cost of a grounded A380 Airbus to be $1,250,000. Airlines are constantly under pressure to streamline their costs and increase their revenues. The IoT in aircraft, therefore, plays a fundamental role in preventing ‘Aircraft-on-ground’ (AOG) events and ensuring the plane is taken to the skies at maximum. AOG events are costly, causes a major interruption in operations leaving aircraft grounded for a significant period of time.

Alaska Group Operating Expenses (2014), From DOT Form 41, Annual Report

To maximize uptime and ROI therefore, it is critical for airlines and OEMs to find solutions to keep AOG events at a minimum.

IoT is a revolution in the aerospace industry that is transforming every part of this sector from aircraft manufacturing and assembly to maintenance and other areas of flight safety. The following four top priorities need to be considered when building or improving on a successful IoT strategy:

1 The Connected Factory

2 The Connected Aircraft

3 The Connected People

4 The Connected Supply Chain

IoT: The Promise and Potential

The benefits of passenger aircraft are rapidly changing particularly in business aviation because of existing connectivity and soon it will be enabling an office-in-the-sky experience. We are already managing the aircraft from many places other than the “Cockpit” or “Control Cabin” in real-time and are not very far from those days where passenger aircraft can be unmanned. In the coming years, Airlines will leverage IoT, data analytics, and related methodologies to the maximum to scale up their business models and make them reach new heights. The center of focus will obviously be the aircraft health monitoring side while the passenger-experience side also will not be overlooked. Basically, for Airlines flying in the oceanic environment, connectivity is a major challenge and they can be benefitted from this real-time data which can provide almost accurate aircraft position data and coordinates (latitude and longitude).

The aerospace industry is increasingly trying to position the connected Aircraft as a node in the sky. Therefore, the days are not far when:

Every connected Aircraft will become an active node in the sky, sharing data with other aircraft, ground operational teams, and Air Traffic controllers at speeds that current systems cannot do.

Soon in the future, the connectivity on the aircraft will be equivalent to what we use in our homes. In the future, every aircraft will be connected to each other. Not only will ground teams be able to see clearly how every component on the aircraft is performing, but the flight crew also will be able to share information from other aircraft. This will give rise to improved safety, efficiency and reduce operational costs.

Conclusion

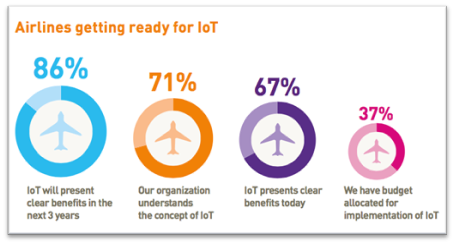

In summary, the IoT in Aerospace represents a tremendous revenue potential and the industry is getting ready to maximize it. A recent study by a leading aircraft engine OEM estimated that the IoT can save airlines more than $30 billion over the next 15- 20 years if it increased fuel savings and improved maintenance by just 1–2% percent. Engine maintenance alone accounts for 43 percent of the total $60 billion yearly maintenance bill. This can be tamed for the biggest revenue opportunity and growth. Two-thirds of them have the view that IoT offers benefits for their Airlines currently. 86% believe IoT will generate benefits over the coming years. 37% of Airlines have already allocated a budget for IoT implementation. Over the next few years, 58% have plans to invest in pilot projects, and 16% are ready to invest in major programs. This will definitely contribute to a steady market share and sustainable growth of the aerospace industry in the coming decade and beyond.

Technological Game Changer — Internet of Avionics things(IOAT) has engulfed Aviation like fire was originally published in Towards AI on Medium, where people are continuing the conversation by highlighting and responding to this story.

Published via Towards AI